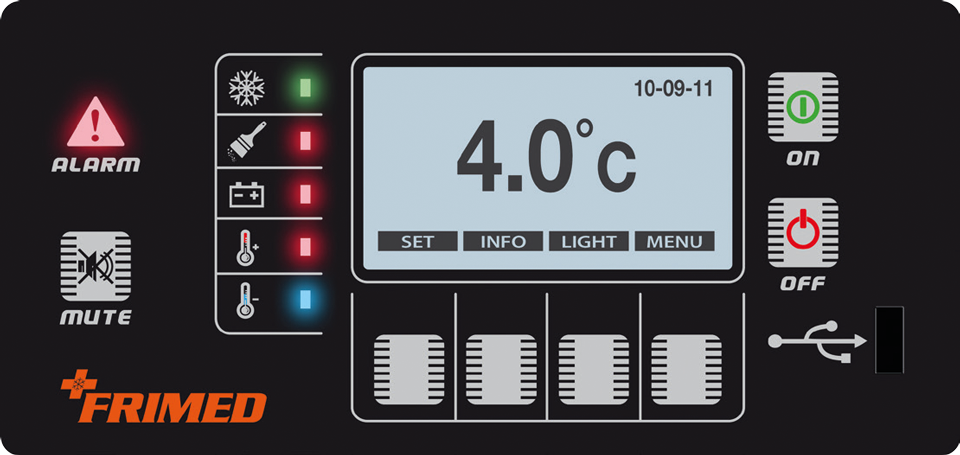

CONTROL PANEL

LGK-2 Digital

Microprocessor control panel with easy-to-read digital display showing inside menu, temperature, set point, date and hour, model of appliance.

Equipment settings and switching off only by means of password.

Continous temperature monitoring with set point and alarms shown on display.

Visual and acoustic alarms through buzzer sound, general alarm warning light,

specific alarm warning light and icon on display.

Alarms included: high and low temperature (adjustable threshold), open door,

condenser efficiency, damaged probes, power failure, run-down battery.

Back up battery(optional) to show temperature on display and generate alarms in case of power failure.

Remote contact to connect the appliance to an external alarm.

GSM module (optional) to send SMS alarm messages showing date, time, cabinet temperature and type of alarm. Possibility to send SMS message to check correct functioning of cabinet.

LAN port (optional) to connect one or more appliances via ethernet on PC for monitoring correct functioning.

USB port to download temperature data and alarms or to reset the appliance.

Data Loggerto record temperatures of last 30 days. Download data on USB pen drive.

Memory for last 20 alarms shown on display.

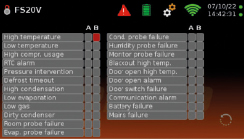

TP-1 Full Touch

Microprocessor control system equipped with:

• Display (Capacitive) Touch Screen True Color 4,3” or 7” (optional)

• USB port to downloading temperature data and alarms; software updates

• LAN network connection (wireless)

• WiFi 802.11n/g

• RS485 serial port between display and control board

The devices of this series are equipped with special functions for the optimization of defrosts and with functions that can be used to obtain energy saving of the unit.

There are 3 inputs for NTC temperature probes (evaporator, condenser, temperature internal chamber), and an input for PT100 probe dedicated to monitoring the internal temperature.

The system architecture is one I / O control card (controller card) and one interface card (4.3 “TFT display card with capacitive touch screen).

The communication between the two boards takes place through an RS485 serial; the Controller board powers the Display board in low voltage (12V).

WIFI MODULE

The wifi module is already included in the standard interface card (display) for possible connection to the cloud [optional with license]

PASSWORD

IThe system is password protected at different levels:• operator [normal user]

• control [control user]

• service [service user]

• factory [factory user]

Passwords (except the factory one, not accessible) can be customized to avoid improper use of the system.

Videographic display of temperature trends, historical alarms that can be consulted directly on the display.

ALARMS

The controller has an internal buzzer for acoustic signaling of alarms, a dry contact relay for remote alarm connection.

Acoustic-visual signaling (with red triangle alarm symbol) of the alarms, even in the power failure if equipped with a back up battery (optional), easy to understand thanks to a detailed list with the meaning of the alarm generated, including:

• High - low temperature

• Dirty condenser

• No power supply – power failure (if with battery as option)

• Open door

• Sensor failure

• Low battery charge (option)

• Communication alarm

Password protected switching on and off controller to avoid deactivation of the fridge by unauthorized personnel

DATA LOGGER

Electronic recording system of temperature and alarm data, with large memory, downloadable on USB key. Sampling interval of 30sec or greater.

CLOUD system (as option)

Connecting and remotely controlling the instrument will no longer be a problem.

The electronic system has an integrated WIFI connection module.

Once online, thanks to the specifically developed Cloud platform (optional, to be quoted), it is possible to remotely intervene on the unit. Available connection with VNC/ Websocket technology that replicates the instrument interface on a PC giving full access to the instrument.

The CLOUD system also simplifies the identification of any error directly remotely so as to allow the service to reduce or even cancel the intervention time and troubleshooting.

The system allows archiving and downloading of historical temperature and alarm data.

It is possible to receive by e-mail a pdf attachment containing the data download, both in graphic and numerical form.

The dispatch can be daily, weekly or cadenced according to the operator’s choice.

ConnectInFri - cloud system

AVAILABLE ON TP-1 FULL TOUCH CONTROL PANEL

To correctly store medicines, vaccines, blood and general biological material, a “simple” refrigerator is not enough.

Today, more than ever, the optimal storage of biological material, medicines, and so on, has not

only an economic but also a social value.

ConnectInFri, is a specifically created cloud to connect and control your refrigerator or freezer remotely, with access via your mobile phone, tablet or computer.

With secure password-protected access to the ConnectInFri platform, you can remotely view and access your refrigerator’s control panel where you can view the parameters and change them if necessary.

ConnectInFri features:

VNC (Virtual Network Computing) remote control:

this is the software application to access/control your refrigerator, thus allowing you to control the unit and use it as if you were standing right in front of it.

This aspect, which is unique in this field of application (Medical Refrigeration), has several extremely ignificant advantages in terms of efficiency, stored product control and cost savings, namely:

a- Possibility for the Service (or whoever is in charge of technical assistance) to control the machine without the end user having to intervene in any way to analyse the situation and reach a diagnosis of the possible problem without physically intervening on site.

b- Possibility to interact with the end user (e.g., co-worker/employee) without being physically present, in the event of functional or purely instructional problems.

2.Data Backup

A backup of the unit’s data has been implemented in the web clouding infrastructure. Naturally, it will always be possible to download such data directly from the unit itself, via the USB port on the display (circular queue of about 12 months), but it will also be possible to download and save such data within the portal itself (for 10 years).

3. Automatic report sending

You can choose to automatically send an e-mail with the daily/weekly/monthly pdf report of the unit’s temperature/alarm data, to an e-mail address set by the user

Through using ConnectInFri, the person in charge of the laboratory, technical department, etc., will be able to:

- View the operating progress of their equipment

- Remotely change the temperature

- Manage alarms

- Manage scheduled maintenance by means of programmable memos

- Analyse energy consumption

- Store data records in folders and print them out by selecting the desired period

ConnectInFri security

Communications are made through secure authentication.

All information (values, alarms, generator data) is stored in a secure, non-public database.

Passwords are irreversibly encrypted so that no one but the user can know the credentials.

The cloud guarantees the use of the most up-to-date security standards and is 100% compliant

with the GDPR (General Data Protection Regulation).